How to Create an Unbeatable Sales + Ops (S&OP) Planning Strategy

Casey O'Connor

Sales and operations planning — usually known as S&OP — is a process that businesses undertake in order to balance their inventory supply with customer demand.

S&OP aligns the marketing, product development, manufacturing, sales, and finance departments, along with the C-suite of executives, to make supply chain decisions with profitability in mind.

Designing an S&OP strategy requires immense organization, coordination, and cooperation. It can be challenging to come to a consensus with so many stakeholders involved in the process.

In this article, we’ll go over everything you need to know about how to design an S&OP planning strategy, including why it’s so crucial for a profitable business, who needs to be involved, and best practices to ease the process.

Here’s what we’ll cover:

- What Is S&OP?

- Why Is S&OP Important?

- How Do You Build a Sales and Operations Strategy?

- Best Practices for S&OP

What Is S&OP?

Sales and operations planning (S&OP) is a collaborative process between several teams within a business organization. The process is designed to address the needs of many teams — finance, marketing, product development, manufacturing, sales, sourcing, customer satisfaction, executive, and others, depending on the organization — while balancing supply and demand.

S&OP is a rigorous and ongoing process. It typically encompasses operational plans 18 months to 36 months into the future, and is evaluated and updated on a weekly, monthly, and/or quarterly basis.

The goals of the S&OP planning process are as follows:

- To create more effective supply chain management

- To provide a holistic view of the resources available in an organization relative to the needs of the market

- And to give businesses the data and predictive analysis they need to improve their decision-making processes

The sales and operations planning process support both strategic and tactical planning. On the strategy side, the process provides insights into how changes in demand may shift supply or workforce needs. Tactically, this kind of supply chain planning helps all stakeholders create and adhere to a production plan, a business schedule, and a material requirements plan (MRP).

To note, S&OP is sometimes conflated with integrated business planning (IBP). While the two processes are certainly similar — both require integration among several teams and address the fluid nature of long-term business planning — IBP typically focuses more heavily on the financial aspects.

Why Is S&OP Important?

One of the most important components of an effective S&OP process is that it allows teams to address “what-if” scenarios. The process gives businesses insights into how they may need to adapt according to possible changes in the market or supply chain.

It also enables businesses to aggregate their needs, insights, and resources in a way that mitigates risk and optimizes profitability while fully meeting the needs of the customer.

There are many advantages to implementing an S&OP planning process. Above all, this kind of collaboration optimizes profitability. It helps ensure that companies are maximizing their resources by planning for many possible scenarios, and gives them the insights needed to pivot in their strategy if need be.

This kind of flexibility reduces waste, lowers inventory, and ultimately improves the bottom line.

S&OP planning also helps ensure a successful customer service strategy. Because the process is meant to be holistic and high-level, the needs of the customer are carefully considered against the needs of the business.

Although the process is time-intensive and ongoing, S&OP actually creates a shorter planning cycle. With the right S&OP software and a collaborative mindset, businesses can leverage the S&OP process to stay on top of their supply chain needs, sales forecasts, and customer success metrics.

Finally, businesses that faithfully adhere to an S&OP process benefit from improved decision-making. The process requires routine and systematic data reporting and regular adjustments to forecasts. The needs of all stakeholders are taken into account, which helps multiple teams collaborate to achieve the same overarching goals.

How Do You Build a Sales and Operations Strategy?

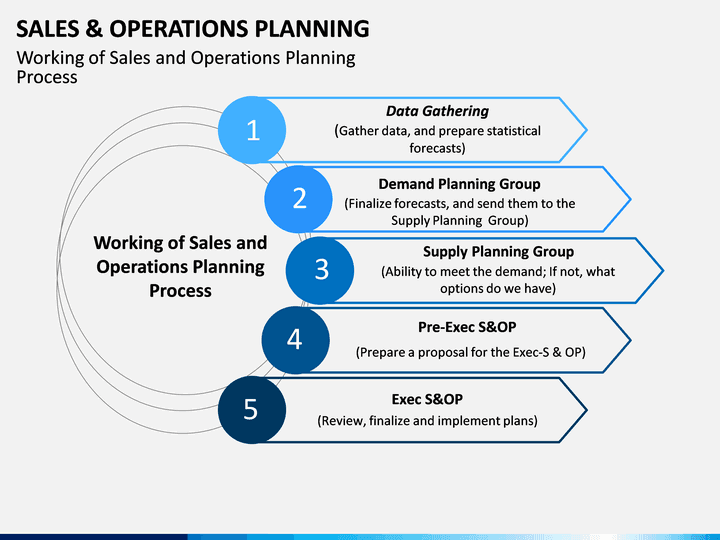

Although the process is rigorous, there is a well-defined order to execute a sales and operations strategy.

The following steps will help your teams complete the process efficiently. You can tweak or adapt them to meet the unique needs of your specific organization.

Gather Your Data

S&OP planning is a data-driven process. Before you come to the table, ensure you have clean and up-to-date data and KPIs. Specifically, you’ll be looking at the following:

- Forecast accuracy (demand and production)

- Order cycle time

- Inventory turnover

- Capacity utilization

- Percentage of on-time delivery to customers

- Intake vs. budget

- Accuracy in order delivery

- Total sales in a period, and forecast accuracy for that period

- Gross margin

- Lead times and procurement schedules

- Working capital versus plan

You’ll also want to specify which teams and stakeholders will be involved in the process.

You may want to assign data-collection tasks to each of these team members.

Product Review

Your sales operations manager and product development team should bring to the table an analysis of the health of the products currently on the market. If you plan to introduce new products, you’ll also want to address how that may impact the existing products (also known as cannibalization).

Demand Planning

In this stage of the process, your teams will address demand forecasting. Tasks here include updating sales forecasts using a combination of sales, marketing, and product data.

This stage should also include an analysis of competitors’ behaviors, as well as new market trends, market volatility, or any other external market influences. The demand plan can be measured in terms of revenue or units.

Supply Planning

Once the demand plan is finalized, teams work together to create a supply plan. This component needs to balance customer demand with inventory and operation costs. The supply plan should outline how resources will be used and should be designed with the demand plan in mind.

The supply planning stage also needs to take into account potential variations in the landscape as time goes in. Here is where teams will run various “what-if” scenarios to prepare for as many outcomes as possible, such as anticipated disruptions in production. The goal here is to reduce risk.

Pre-S&OP

Once the demand and supply plans are complete, it’s time to fine-tune the report. The overall goal of this stage of the process is to cross-check and align the various teams with a stake in the S&OP plan.

Leaders of the various departments involved in the process should review the plan carefully. Expect discrepancies to exist at the beginning of this stage; the purpose of this step is to address those gaps in real-time, if possible, and come up with contingencies and alternate strategies for any potential issues that can’t be reconciled before execution.

Executive S&OP

In this final stage, the S&OP plan is finalized and released to the top-level executive team. The intention is for the C-suite to approve the plan and release it for implementation. The S&OP plan should also call attention to specific decision-making points so that leaders of each team can prepare for them ahead of time.

It’s worth noting that some teams add an additional, specific step after the demand plan: the financial planning stage. Some organizations, though, believe that the financial component of the S&OP should be continuously addressed throughout the process.

Regardless of how your company chooses to structure the financial discussion, it’s crucial that profitability and operating costs are addressed thoroughly within your S&OP plan.

Best Practices for S&OP

It should be clear by now that the S&OP process is a rigorous one. It requires a significant amount of technical and financial analysis, inter-team collaboration, and commitment to progress monitoring.

Keep the following best practices in mind in order to help the process run as smoothly as possible.

Align Your Departments

For S&OP planning to be successful, multiple teams need to work together on an ongoing basis. Leaders should work to create an environment where cross-departmental collaboration is encouraged and even expected. Teams need to be well in-tune with one another’s goals, progress, and challenges; discourage departmental silos at all costs.

Encourage Healthy Conflict

By that token, it’s also okay for your teams to disagree. The S&OP planning process will naturally create some tension, conflict, and disagreement as teams work to harmonize the various needs and concerns of their respective departments, as well as those of the customer base. Team leaders would be well-served to offer training in healthy conflict resolution.

Get Executive Support

The S&OP planning process will be fruitless if you don’t have the support of executive leadership. Ultimately, they will allow or disallow your proposed resource management plan, so they need to be kept in the loop about the priorities and needs of the various teams and the process as a whole.

Keep an Eye on Your Metrics

Effective S&OP planning relies on thorough, methodical, and frequent data analysis. Team needs will vary by organization, but aim to analyze your current metrics at least monthly; some teams may even opt for weekly analysis. A higher-level strategy assessment should also take place at least quarterly.

Find the Right Technology

In decades past, most teams with an S&OP process in place could get away with using spreadsheets to house and analyze data. However, in today’s fast-paced sales world, the S&OP process is nearly impossible without the right technology to support it.

There are many powerful S&OP planning software tools available to help teams analyze data, prepare reports, and pull actionable insights that are ready to be implemented. Make sure your team is equipped with the tools they need to execute the S&OP process to its fullest extent.

Does your team have an S&OP planning strategy? How has it transformed your business?

If you don’t have this process in place yet, start by monitoring the metrics outlined in this article and sharing insights with the various teams that hold a stake in the process. This analysis will get the ball rolling and have you well on your way to a well-run S&OP planning process.

Get sales tips and strategies delivered straight to your inbox.

Yesware will help you generate more sales right from your inbox. Try our Outlook add-on or Gmail Chrome extension for free, forever!

Related Articles

Casey O'Connor

Casey O'Connor

Casey O'Connor

Sales, deal management, and communication tips for your inbox